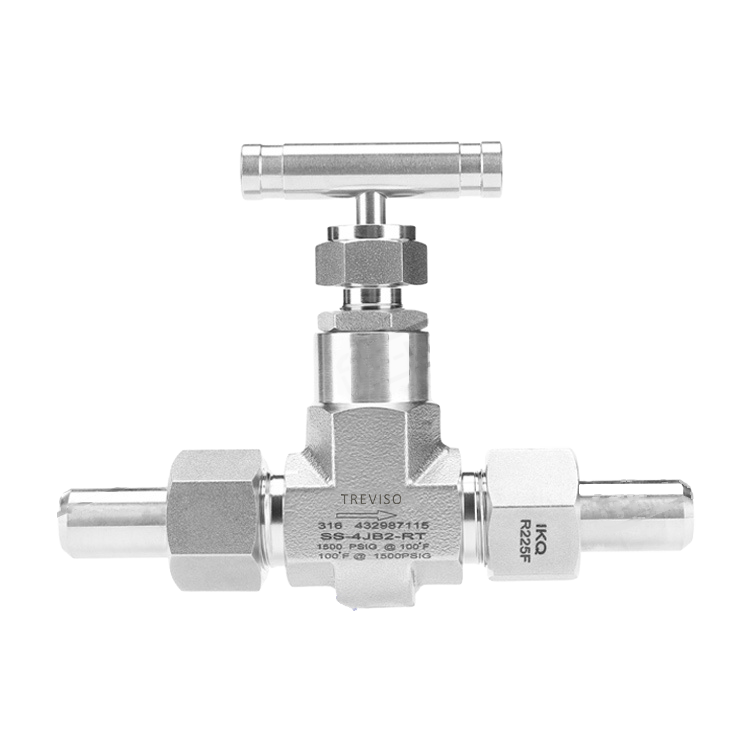

The Integrated Forged Needle Valve DN5 – DN25 is designed with a one-piece forged valve body to ensure maximum strength, durability, and leak-proof performance. Featuring a two-section valve stem design, the upper valve stem thread is specially hardened for increased wear resistance, while the lower valve stem surface is roll-hardened to enhance longevity and smooth operation.

This advanced design isolates the upper valve stem thread grease from the system media, extending valve life and maintaining system cleanliness. The non-rotating lower valve stem provides vertical movement rather than rotational lift, reducing friction and wear between the valve seat and valve head during each operation. Additionally, the handle is securely locked with screws at both ends, offering exceptional stability and long-term reliability.

Technical Specifications

- Valve Body Materials: Carbon Steel, Stainless Steel, Copper, Alloy 400 (Monel)

- Size Range: DN5 – DN25

- Pressure Rating: Up to 10,000 psig (689 bar)

- Working Temperature: -54°C to 649°C (-65°F to 1200°F)

- End Connections: Threaded, Welded, Ferrule

- Operation: Manual

- Applicable Media: Water, Gas, Oil

- Compliance Standards: API, ASME, ASTM, ANSI, BS, DIN, JIS, ISO, GB

Applications

The Integrated Forged Needle Valve is ideal for high-performance and high-pressure applications across multiple industries, including:

- Petroleum & Oil Refining

- Chemical Processing

- Pharmaceutical Manufacturing

- Testing and Laboratory Equipment

Recensioni

Ancora non ci sono recensioni.