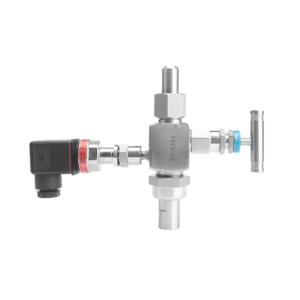

Precision Flow Control | Reduced Wear Design | Reliable Performance

The Non-Rotating Stem Needle Valve is engineered for precision fluid regulation, offering superior control, reduced maintenance, and long-term reliability in high-performance systems. Its non-rotating stem design prevents rotational friction during operation, significantly minimizing wear on the valve seat and packing—making it an ideal choice for high-cycle or high-pressure applications.

Constructed from high-quality materials such as stainless steel, brass, and Alloy 400 (Monel), this valve provides excellent corrosion resistance and mechanical strength. It supports a wide temperature range and is compatible with various media including water, gas, and oil.

Technical Specifications:

- Valve Body Materials: Stainless Steel, Brass, Alloy 400 (Monel)

- Size Range: DN5 – DN25

- Pressure Rating: ≤3000 psig (206 bar)

- Working Temperature: -20°F (-28°C) to 450°F (232°C)

- End Connections: Threaded, Welded, Ferrule

- Operation: Manual

- Compliance Standards: ASME B16.34, ASME B16.11, ASME B1.20.1

Applications:

This valve is widely used in:

- Petrochemical and Chemical Industries

- Coal Gas and Natural Gas Systems

- Liquefied Petroleum Gas (LPG) Applications

- HVAC Systems and Industrial Flow Control

Recensioni

Ancora non ci sono recensioni.