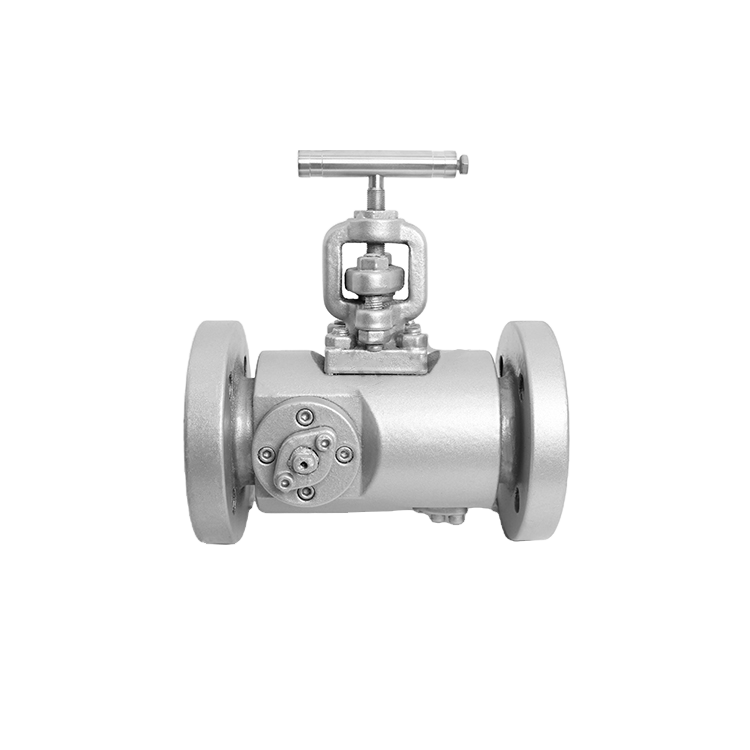

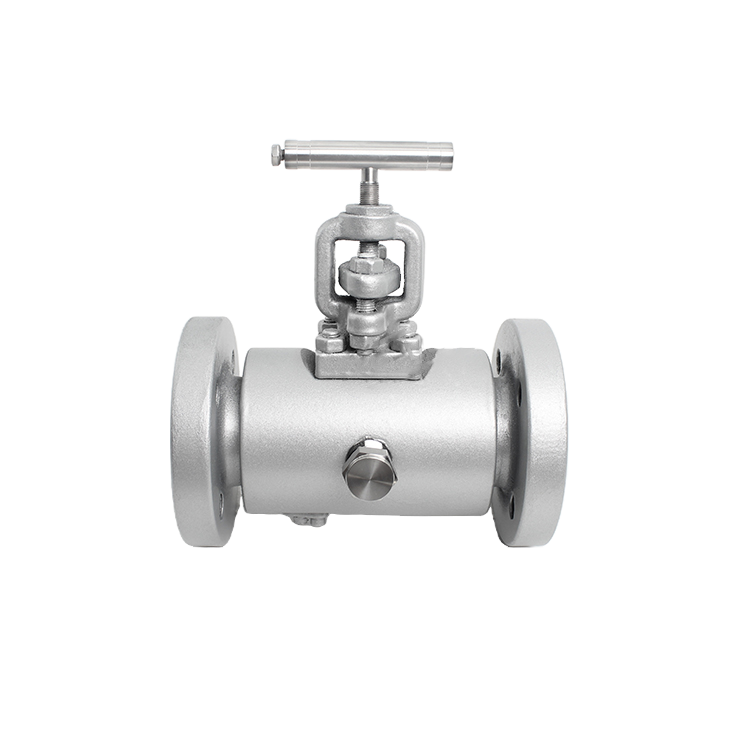

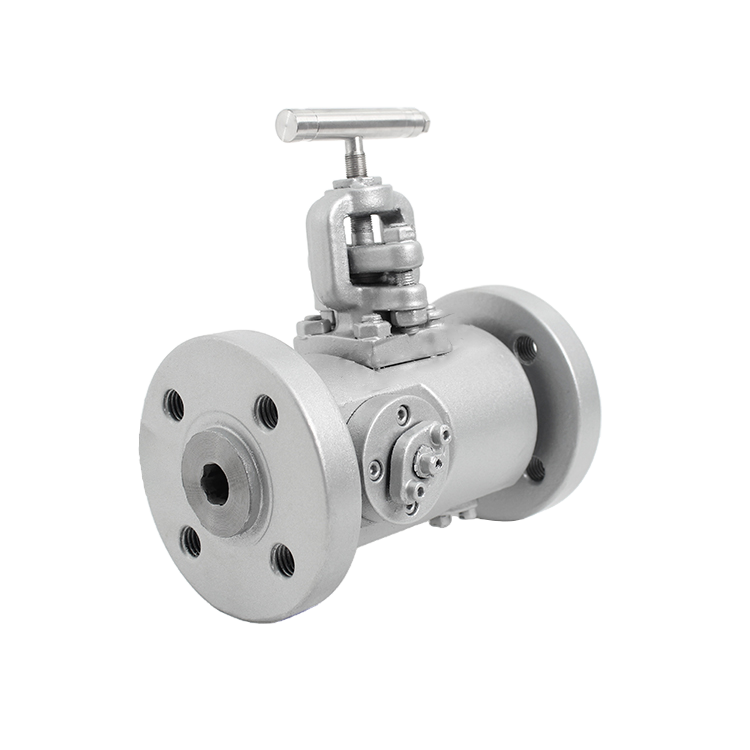

Precision Isolation and Safety for Critical Fluid Control Applications

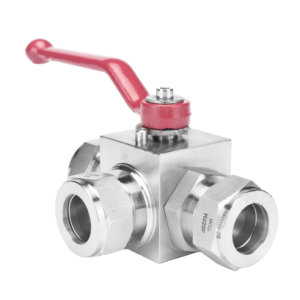

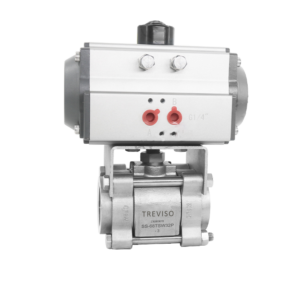

The DBB Valve, also known as a Double Block and Bleed Valve, is a high-integrity valve solution engineered to provide positive isolation of critical flow lines. It offers two separate sealing surfaces (double block) with a bleed mechanism in between, allowing for safe maintenance, venting, or pressure relief—without shutting down the entire system.

This advanced valve is ideal for applications requiring zero leakage, enhanced safety, and easy inline maintenance. Built with high-grade materials such as carbon steel, stainless steel, copper, and alloy steel, the DBB valve is suitable for extreme pressure and temperature conditions in oil and gas, chemical, power generation, and water treatment industries.

🔧 Technical Specifications

-

Product Name: DBB Valve (Double Block and Bleed Valve)

-

Materials: Carbon Steel, Stainless Steel, Copper, Alloy Steel

-

Size Range: Customizable upon request

-

Pressure Rating: Up to 10,000 PSI or more (based on design)

-

Temperature Range: Typically -29°C to +540°C

-

End Connections: Threaded, Flanged, Ferrule, Welded

-

Operation Methods: Manual, Pneumatic, or Electric

-

Applicable Media: Oil, Gas, Steam, Water, and Chemical Fluids

-

Design Standards: API 6D, ASME B16.34, ANSI, ISO, ASTM, GB

🌍 Industries Served

-

Oil & Gas Exploration and Processing

-

Chemical & Petrochemical Facilities

-

Power Generation (Thermal, Nuclear)

-

Offshore Platforms & Marine Systems

-

Industrial Water and Steam Lines

Recensioni

Ancora non ci sono recensioni.